Flange Machines

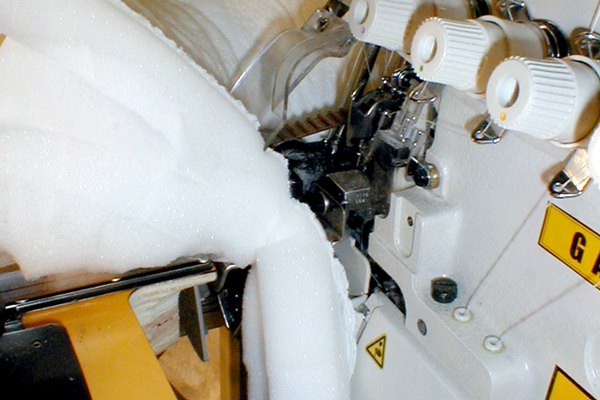

Global Systems Group builds the mattress industry’s top flange machines, the Porter PFM-4000 and the Galkin X-5. They sew the thickest, densest quilt material in the industry at the fastest rates. Preparing mattress panels for build-up operations requires an effective flange operation.

A variety of other flangers from GSG provide ergonomic and semi-automatic flanging systems.